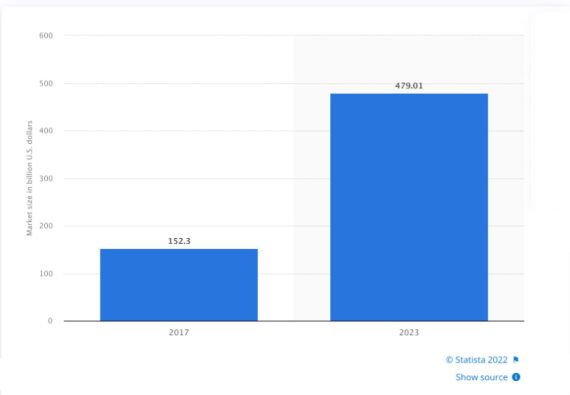

There has been a lot of buzz and hype around smart manufacturing and smart factories. No wonder, the global market for smart manufacturing solutions is projected to reach $506.33 billion by 2027.

One of the main reasons for this is the drive to remain competitive as increased automation plays out in many industries. The need for OEMs to be competitive, flexible and resilient has become key, especially as global manufacturing has felt the full force of the Pandemic, and supply chain vulnerabilities and interconnectedness has been laid bare.

Experts say that the next decade will bring even more change

The manufacturing industry is becoming more fragmented and diverse, with a multitude of companies competing for customers in an increasingly interconnected world. This means that companies are competing not just for customers but also for components, materials, and suppliers. And this competition is happening in a global market that often requires quick response times and quick decisions.

Along with this, issues such as the Pandemic and Brexit after-effects (creating more paperwork and friction), and a skilled worker shortage (not forgetting a HGV crisis in the UK and Europe, container ships queueing off the US West Coast or Shanghai waiting to unload) have laid bare how the global supply chain can become disrupted. It has brought to front of mind for many in OEM management the need to build far greater resilience, and potentially reengineer, current supply chains.

The groundbreaking concept of the smart factory has long been heralded as the next frontier in manufacturing. However, the transition to such a system requires a significant investment in expertise, time, and money. To move from a traditional manufacturing system to a smart system a range of factors need to be taken into account.

OEM smart manufacturers require:

— expert logistics partners

— collaboration with suppliers

— reconfiguration of production processes

— integration of technology with people

Logistics partners are crucial for the success of a smart factory. In order to optimise production processes and maintain high quality standards, suppliers need to be on-board.

The best way to plan a transition is to work with a smart logistics partner to understand and fully configure the production process from component, through assembly and manufacture, to provision and after-market service.

Ready to find out more?

Drop us a line today to explore our services